Articles > Innovations in Nano Manufacturing

Introduction

Nanoscale additive manufacturing is a cutting-edge technology that allows for the precise creation of structures and components at the nanoscale level. This innovative process offers a wide range of potential applications, from creating advanced nanoelectronics and nanomaterials to producing customized medical devices and pharmaceuticals. In this discussion, we will delve into the definition and overview of nanoscale additive manufacturing, exploring the fundamental concepts and methods used in this emerging field. We will look at the unique capabilities and potential impact of this technology, as well as the challenges and opportunities it presents in various industries.

The importance of nanoscale additive manufacturing lies in its ability to fabricate intricate and precise structures at the nanoscale level, offering significant potential impacts across various industries. In aerospace, the technology allows for the production of ultra-lightweight and high-strength components, which can improve fuel efficiency and reduce emissions. In the medical device industry, nanoscale additive manufacturing enables the creation of customized implants and drug delivery systems with enhanced biocompatibility and performance. Additionally, in the electronics sector, the technology can be utilized to manufacture smaller and more efficient electronic devices.

Nanoscale 3D printing also offers numerous benefits, such as the ability to produce materials with controlled microstructures, which can enhance their mechanical, electrical, and thermal properties. Furthermore, the technology can significantly improve the strength-to-weight ratio of components, leading to lighter yet stronger materials that are crucial for aerospace and automotive applications. Overall, nanoscale additive manufacturing holds great potential for revolutionizing various industries and advancing technological innovation.

Nanoscale additive manufacturing refers to the production of tiny objects on a scale of one billionth of a meter. This emerging technology has the potential to revolutionize various industries, from electronics to medical devices. Understanding the 3D printing process in nanoscale additive manufacturing is essential for harnessing its full potential. This process involves the layer-by-layer deposition of material to build a three-dimensional object at the nanoscale. From design to printing, precision and control are crucial at every step to achieve the desired outcome. In this article, we will delve into the intricacies of nanoscale additive manufacturing, exploring the techniques, materials, and applications that make this technology so promising for the future.

Traditional 3D printing, also known as additive manufacturing, involves the layer-by-layer deposition of material to create a three-dimensional object. The process begins with the creation of a 3D digital model, which is then sliced into thin horizontal cross-sections. The printer then builds the object by stacking these layers on top of each other using various materials such as plastic, metal, ceramics, and composites. This technique has a wide range of applications, including prototyping, product development, and manufacturing of custom parts and components.

In contrast, nanoscale additive manufacturing operates on a much smaller scale, utilizing nanoscale materials and precise manipulation at the molecular level to create extremely small structures and devices. This technique offers the ability to create intricate and precise structures, making it suitable for applications in the fields of electronics, medicine, and materials science.

The strengths of traditional 3D printing lie in its versatility and wide range of material options, while nanoscale additive manufacturing excels in precision and potential for advanced applications. However, traditional 3D printing may have limitations in achieving high precision at the nanoscale, while nanoscale additive manufacturing materials and techniques may be more limited and costly.

3D printing technology can be adapted for nanoscale additive manufacturing by utilizing advanced methods and materials in nanotribological printing. Nanoscale additive manufacturing involves building up solid structures at the nanometer scale, typically using materials such as polymers, metals, and ceramics. Nanotribological printing, a technique that combines 3D printing with nanoscale friction and wear studies, allows for precise control over the deposition of materials at the nanoscale.

Challenges in scaling 3D printing down to the nanoscale include the need for high precision and resolution, as well as the development of specialized materials and printing processes. However, the opportunities in nanoscale additive manufacturing are vast, including potential applications in nanotechnology and advanced materials such as nanoelectronics, nanostructured coatings, and biomedical devices. By harnessing the capabilities of 3D printing technology at the nanoscale, researchers and manufacturers can explore new frontiers in material science and engineering.

In conclusion, the adaptation of 3D printing technology for nanoscale additive manufacturing, particularly through the use of nanotribological printing, offers exciting prospects for the development of advanced materials and nano-sized devices in various fields of science and technology.

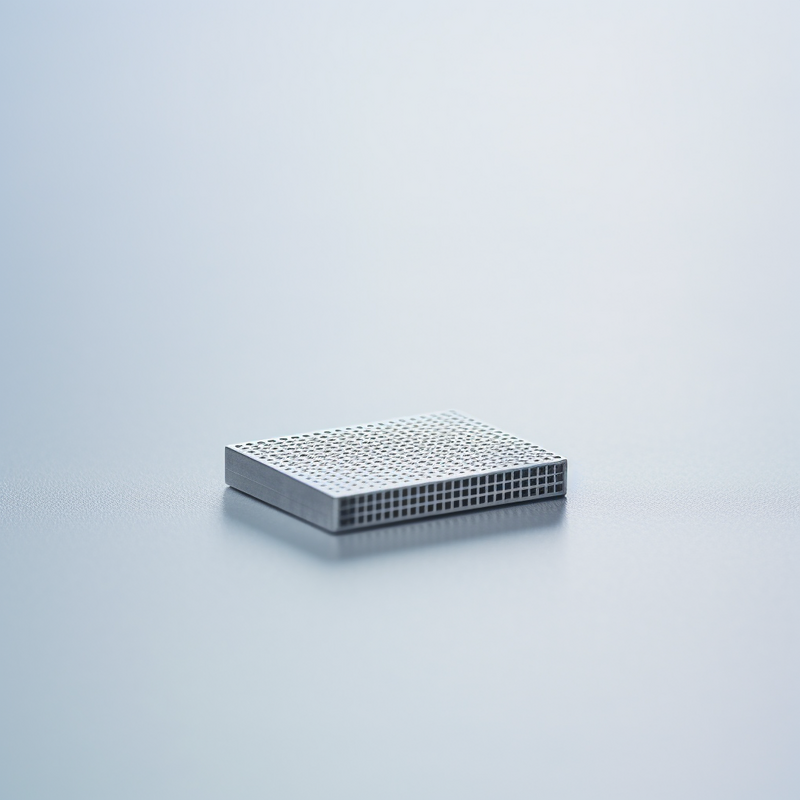

A nanoscale 3D printer operates on the same basic principles as traditional 3D printers, but on a much smaller scale. Key components of a nanoscale 3D printer include a nanopositioning system, nanofluidic chambers, and a precision dispensing system. The nanopositioning system enables precise movement of the printing nozzle, while the nanofluidic chambers hold the printing material at the nanoscale.

Nanoscale 3D printing methods often utilize additive manufacturing techniques such as electron beam lithography or focused ion beam. These methods allow for the creation of intricate structures at the nanoscale using materials such as polymers, metals, and ceramics.

Challenges of nanoscale 3D printing include the need for extremely high precision and the potential for material limitations due to the small scale. However, the benefits include the ability to create complex nanoscale structures with high resolution and accuracy.

Several techniques and technologies are being developed for nanoscale 3D printing, including two-photon lithography, DNA origami, and directed energy deposition. These advancements aim to further improve precision, speed, and material options for nanoscale 3D printing.

Nanoscale additive manufacturing has revolutionized the production of small-scale components and devices, allowing for high precision and intricate designs. The materials used in this process play a crucial role in determining the quality and performance of the final product. From metals and ceramics to polymers and composites, a wide range of materials are employed in nanoscale additive manufacturing to create durable, functional, and finely detailed structures. Understanding the properties and capabilities of these materials is essential for achieving the desired results in this cutting-edge manufacturing technique.

Nanoscale 3D printing traditionally has been limited to a narrow range of materials due to the challenges of achieving precision at such a small scale. However, ASU Assistant Professor Kenan Song and his team have developed a new method called Multiphase Direct Ink Writing, which has the potential to enhance precision with a wider range of nanomaterials. This method allows for the printing of multiple materials simultaneously, enabling the creation of complex structures with high precision.

The range of materials suitable for nanoscale 3D printing using this method includes various nanomaterials such as polymers, ceramics, metals, and composites. This advancement in nanoscale 3D printing technology opens up new possibilities in fields such as sensors, soft robotics, energy devices, and regenerative medicine. For example, the ability to print multi-material structures at the nanoscale could lead to advancements in creating more efficient and responsive sensors, softer and more flexible robotic devices, high-performance energy devices, and custom implants for regenerative medicine.

Overall, the Multiphase Direct Ink Writing method has the potential to revolutionize nanoscale 3D printing by expanding the range of materials that can be used, leading to advancements in various fields with its unprecedented precision and versatility.

Nanoscale additive manufacturing requires functional materials with specific properties to achieve micron-scale resolutions. Metals, such as titanium and aluminum, are commonly used for their strength, conductivity, and thermal properties, making them ideal for aerospace and electronics applications. Ceramics, including alumina and zirconia, offer high temperature resistance and biocompatibility, making them suitable for medical devices. Glass-ceramics, such as lithium disilicate, combine the properties of glass and ceramics, making them useful for dental and optical applications.

These materials are used in nanoscale additive manufacturing processes, such as laser powder bed fusion and electron beam melting, to achieve high precision and resolution. In aerospace, nanoscale additive manufacturing can be used to produce lightweight parts with complex geometries. In the medical device industry, it can enable the production of patient-specific implants and prosthetics. In the electronics industry, it can be used to create high-performance components with intricate features. Overall, functional materials in nanoscale additive manufacturing have the potential to revolutionize various industries by enabling the production of complex, high-performance parts with micron-scale resolutions.